Boat Plans

For the DIY-er Yves-Marie has assembled a collection of boat plans designed for the home boat builder for those that prefer their own craftsmanship. Easy to follow plans, all of the information you'll need, and well thought out designs. If you should require further consultation Yves-Marie is available for design alterations, and advice should you need it.

34' Sea-Weed - wood

34' Sea-Weed - wood

Design #940

Plans for this plywood centerboarder, shallow draft cruiser include the following sheets.

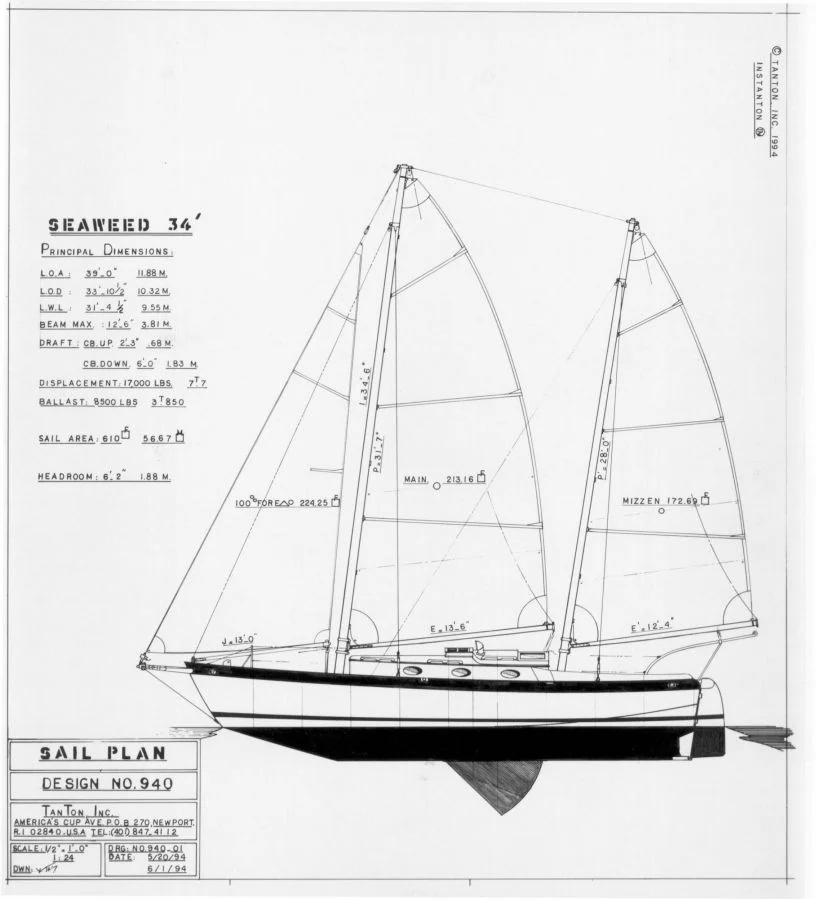

L.O.A 34’-0” xL.W.L 31’-4” x Beam 12’-0” x Draft 2’-3/ 6’-0”” x Dspl. 17.000lbs. x SA. 610 sq/ft.

10.36M. 9.55M. 3.66M. 68.5cm./ 1.83M. 7T 711 56.7 sq/m.

DRG. 940-01 Sail Plan. Bermudan Ketch. Scale: 1/2"= 1'-0" 1:24

DRG. 940-02 Masts and Rigging 1/2"= 1'-0" 1:24

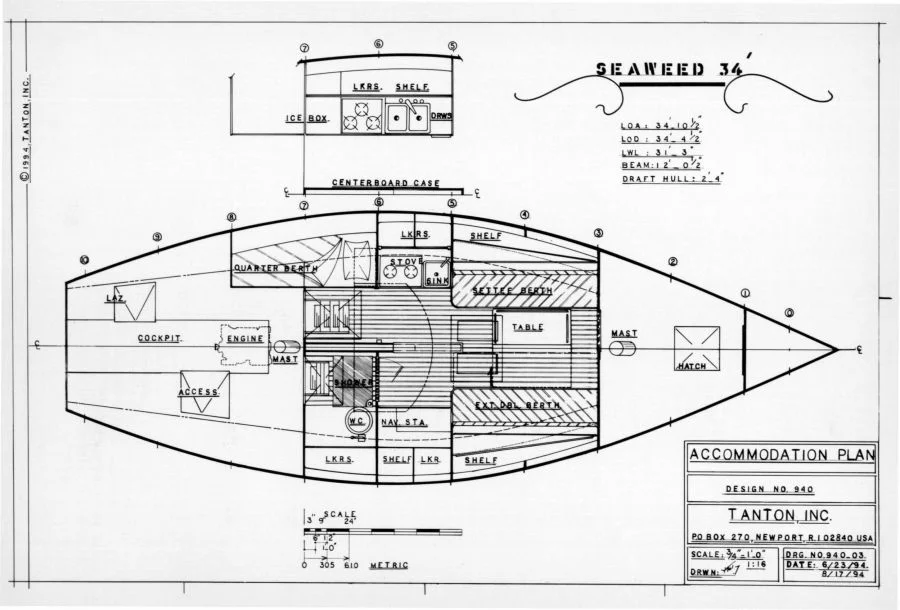

DRG. 940-03 Accommodation Plan. 3/4"= 1'-0" 1:16

DRG. 940-04 Lines Plan. Table of Offsets. 3/4"= 1'-0" 1:16

DRG. 940-05 Midship construction section. 3"= 1'-0" 1:4

DRG. 940-06 Construction Plan. ¾”= 1’-0” 1:16

DRG. 940-07 Centerboard Plan. 3”= 1'-0" 1:4

DRG. 940-08 Rudder Plan.. 3"= 1'-0" 1:4

DRG. 940-09 Deck Plan. 3/4"= 1'-0" 1:16

US$995.00

SEA-WEED

Timber List for Hull, Bulkheads and Building Stocks.

Items excluded from this list are: much of the interior joinery, moldings and finishing touches. Masts.

Lumber: Douglas fir, vertical grain, kiln dried, " select"; or suitable equivalent.

Philipine Mahogany and other exotic woods as desired.

1" X4" = 419'

2" X4" = 450'

2" X6" = 26'

2" X3" = 108'

2" X8" = 34'

Plywood: All Douglas Fir D.F.P.A" A-B" faces.

3/4" 23 sheets. 7- ply exterior. Bottom panel and bulkheads.

1/2" 10 sheets. 5- ply exterior. Side panels.

3/8" 25 sheets. 3 or 5- ply exterior. Topsides and deck.

Allowance has been made for reasonable wastage and scarfing. All dimensions and quantities are approximate.

DESIGN NO. 940SEAWEED 34.

Seaweed was conceived during a boat delivery down the Intracoastal Waterway. I wanted a "Prince of Tides" for a boat. Besides the waters of Florida and Chesapeake Bay, the problem of cruising in shoal waters abounds in areas around the Bahamas Islands, Martha's Vineyard, Nantucket, etc… to name only my neighborhood. A "Gunkholer's Delight" was the design research I embarked upon on that trip. I wanted her to be popular in order to share the result with others. I wanted her to be commercial enough to pay for the hundred of hours always involved in a project like this, where I take an investment approach on my time and my ability to sell. Well; here is " Seaweed." She can go anywhere where there are only two and half feet of water. The absolutely flat bottom is the base upon which to erect what is an "InsTanton" hull shape: one constant open angle describes the topsides, sides of the hull below water and fore and aft. This is very simple to comprehend if you or I have only one constant angle pattern to draw and to make. The beam at 12' is substantial due to that method of design and is advantageous in keeping this boat on her feet at low angle of heel. The consistency of this geometry in space is the beauty of this system. The transom stern is the logical answer to a maximum waterline length of 31'-4 1/2 ": I wanted to keep the length on deck less than 34 feet. I rather like the abrupt hull underwater profile with the board down. It reminds me of the "Coke Bottle" shape of jet fighters designed on the " Area Rule" principle. Above the water, the constant flare brings shape into the topsides. The sheer is terminated and accentuated by a curvaceous toe-rail or covering board set on a deck that is flat in profile. The roof, giving 6'-3" of interior headroom, is traditional. The side decks are 26" wide for sure footing and are kept parallel to the deck edge to simplify the construction of deck beams. Yes, there is a sense of tradition about this sailboat and that is just fine. To have stability on this boat, the sail plan had to be divided into a ketch rig. Low center of effort in the sail spread is essential to achieve reasonable stiffness, and so is the 50% ballast to displacement ratio. This is possible by attention to detail. Install 75% of the recommended ballast and trim the rest depending on the type of sailing or provisioning contemplated. The displacement is substantial at 17,0000lbs. Fully loaded with cruising gear and stores. Her displacement/ length ratio is 250. I expect performance. She has a centerboard. Now, the last one I designed was on a 73' charter boat. That was a complicated thing with hydraulics and

Whatnot, but efficient. The concept was borrowed from the old "Red Rooster" of my Dick Carter days and was good enough to win the

Fastnet race. This was actually a clever piece of engineering, with the normal turbulence expected at the bottom of the trunk all but

eliminated by a piece of Dacron covering. The cloth was set in two channels and moved fore and aft by a continuous line. The Kodak film

approach. But do not forget to move it if you raise or lower the board!

The design and construction of the whole boat is in Seaweed, largely centered on the centerboard. In order for this sail boat to reach its

full potential it is important to get the board built right and working right. The plans call for a centerboard made of thick layers of plywood

covered by a couple of layers of glass. Make it fair, make it smooth. With its high lift foil definition, it will perform. All the details are in the

drawings of course but I insist on this point. The temptation is to ignore it. Do not. To come back to the sail plan: moderate but adequate.

Count on a light air genoa if you want, and a mizzen staysail to boot the numbers up. Actually, this boat will sail as a Cat-Ketch, an old

favorite rig of mine, very well. She will even sail with the mizzen alone. Maybe you will want a small windward to go on the mizzenmast,

set on the main boom for self-tacking when the main is down. All this is to say that the centerboard allows for vast changes in balance,

and the combinations of the sail plan are endless. The rake of the masts, respectively 7 and 9 degrees helps in the pursuit of that

balance and allows for a very simplified standing rigging of one shroud per side, plus the forestay of course- the closest thing to a free

standing rig. The masts are box section in shape, made of spruce and epoxy. Alternatively, aluminum extrusions can be chosen.

The centerboard trunk, usual with board boats dictates the interior, and often this can be quite limited. I deliberately use the centerboard to

create a double companionway with dual entrances and use the forward bulkhead of the toilet to serve as an athwarship reinforcement to

the trunk. I found this interesting, because it creates an enclosed space where one can change in bad weather without dripping all over

the cabin. With the galley on the opposite side, one is free to arrange a quarter berth or a larger cooking place depending on the boat

priorities. The arrangement plan is skimpy, simply because if you have to build her yourself you have to limit the complications and go for

the necessary. But, I can present a few alternatives to spice up the layout. For instance, the chart table on the starboard side can be lifted

to reach the icebox, or the icebox can be placed opposite with access from the deck and the interior. The main cabin is spacious and is

furnished with an extension double berth on the starboard side. I suppose, if you draw a curtain fore and aft between the centerline of the

centerboard case and the forward end of the cabin, you can create your own private double cabin with access to the head: not bad. A

couple of traditional pipe berths can be thrown in the forepeak, aft of the watertight bulkhead. There is another watertight bulkhead

formed between the last station frame and the transom stern. The engine (Diesel 20 to 40 H-P) is accessible through the cabin behind the

ladders or by its own access on deck. The propeller is protected by a full skeg.

Simple construction with plywood. Yes, the boat is designed for that form of construction and is particularly appropriate with the

"InsTanton" shape and philosophy. The flat bottom is two thicknesses of 3/4" plywood glued together. The lower planking streaks are two

layers of 1/2". The upper planking streaks are 3/4" plywood, with a mahogany sheer strake. The deck is 1/2" plywood covered with cloth

and epoxy. Plywood bulkheads and frames are lofted and shaped before setting them up on the bottom plank and keelson. Longitudinals

and the chines are correctly placed and the rest of the planking is wrapped around these forms, which act as construction molds. The

ballast is handled very straightforwardly by pouring concrete and steel directly on top of the flat bottom to the tune of 8500lbs. (75%

minimum), all enclosed by the cabin sole.

An amateur or a professional shop can put a Seaweed together quite fast, and this one of the points of this exercise. An alternative

method of construction could be glass sandwich construction laid up in a cheap female Masonite mold. Aluminum is possible as well as

steel.

I can envision Harry Pidgeon at the age of forty-four building his legendary 34 footer "Islander" on the beach in California. I believe he

would approve of this project.